Module 1: Government and Private Agencies

– Introduction

– Government Agencies

– Department of Labor

– Department of Health & Human Services

– US Environmental Protection Agency

– US Department of Transportation

– US Department of Energy

– US Nuclear Regulatory Commission

– State Plans

– Code of Federal Regulations

– Scope and Application of HAZWOPER

– Other Organizations

– ANSI

– NFPA

– AGIH

Module 2: Training Requirements

– Training

– Supervisors

– Employees

Module 3: Planning and Organization

– Planning and Organization

– Organization Chart

– Work Plan

Module 4: Health and Safety Plan Part 1

– 10 Elements of a Health and Safety Plan

– Hazard Analysis

– Employee Training

– Personal Protective Equipment

– Specific Medical Monitoring

– Air Monitoring

Module 5: Health and Safety Plan Part 2

– Site Control

– Decontamination

– Emergency Response

– Confined Spaces

– Spill Containment

– New Technologies

– Health Effects

– Acute Exposures

– Chronic Exposures

Module 6: Toxicology Part 1

– Dose Response Relationship

– Toxicity and Hazard

– LD50 and LC50

Module 7: Toxicology Part 2

– Four Routes of Exposure

– Inhalation

– Ingestion

– Absorption

– Injection and Contact

– Chemicals in The Body

– Target Organs

– Chemical Interaction

Module 8: OSHA Exposure Limits

– Factors Determining Toxicity

– Chemical Factors

– Exposure Factors

– Environmental Factors

– Exposure Limits

– PLV

– TLV

– REL

– TWA

– STEL

– Ceiling Limits

– IDLH

Module 9: NIOSH Pocket Guide

– Sections

– 16 sections of NIOSH Pocket Guide

Module 10: Labels and Placards

– NFPA and DOT

– NFPA 704 Diamond

– DOT Placards and Labels

– HAZCOM/GHS

Module 11: Physical Properties

– Water

– Boiling Point

– Flash Point

– Vapor Pressure

– Density

– Solubility

– Melting Point

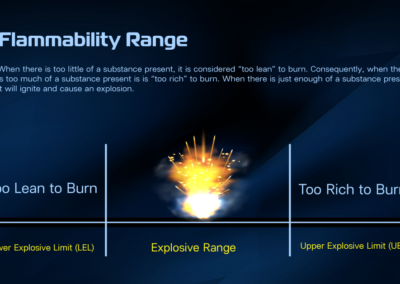

– Flammability

– Phase Diagram of Water

– pH scale

– Radiation Types

– Fire Triangle

Module 12: Hazards Part 1

– Chemical exposure

– Explosion and fire

– Oxygen deficiency

Module 13: Hazards Part 2

– Ionizing radiation

– Biologic hazards

– Safety hazards

– Electrical hazards

– Heat stress

– Cold stress

Module 14: Hazards Part 3

– Cold Stress (cont’d)

– Heat Stroke

– Noise

– Illumination

– Administrative Controls

Module 15: Medical Surveillance

– Developing a Program

– Pre-employment Screening

– Periodic Medical Examinations

– Termination Examination

– Emergency Treatment

– Non-emergency Treatment

– Medical Records

– Program Review

Module 16: Site Characterization

– Offsite Characterization

– Onsite Survey

– Information Documentation

– Hazard Assessment

Module 17: Air Monitoring

– Measuring Instruments

– Site Monitoring

– Personal Monitoring

– Hazardous Waste Site Exposure

Module 18: Personal Protective Equipment Part 1

– Developing a PPE Program

– Selection of Respiratory Equipment

– Positive Pressure Respirators

– Negative Pressure Respirators

– Facepiece Types

– Factors Affecting Respirator Seal

– Assigned Protection Factor

Module 19: Personal Protective Equipment Part 2

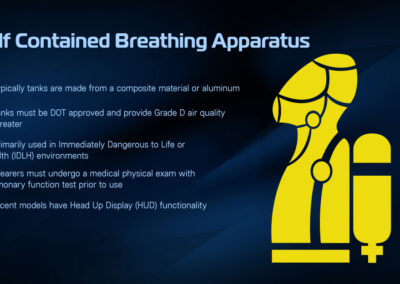

– Self-Contained Breathing Apparatus (SCBA)

– Supplied Air Respirators (SARs)

– Combination of SCBA/SAR

– Air-Purifying Respirators

– Respirator Fit Test

– User Seal Check

Module 20: Personal Protective Equipment Part 3

– Selection of Protective Clothing and Accessories

– Selection of Chemical

– Protective Clothing (CPC)

– Permeation and Degradation

– Heat Transfer Characteristics

– Selection of Ensembles

– PPE Use

Module 21: Personal Protective Equipment Part 4

– PPE Use Continued

– Heat Stress and Other Physiological Factors

Module 22: Site Control

– Site Map

– Site Preparation

– Site Work Zones

– Exclusion Zone

– Contamination Reduction Zone

– Support Zone

– Buddy System

Module 23: Decontamination

– Decontamination Plan

– Prevention of Contamination

– Types of Contamination

– Decontamination Methods

– Effectiveness of Decontamination

– Health & Safety Hazards

– Decontamination Facility Design

– Disposal Methods

Module 24: Drum and Container Management

– Inspection

– Planning

– Handling

– Opening

– Sampling

– Characterization

– Bulking

– Shipping

Module 25: Site Emergencies

– Planning

– Personnel

– Training

– Communications

– Site Mapping

– Safe Distances and Refuges

– Evacuation Routes and Procedures

– Medical Treatment/First Aid

– Emergency Response Procedures

– Documentation