NIOSH Color Coding for Respirator Cartridges and Filters

In HAZWOPER (Hazardous Waste Operations and Emergency Response), selecting the correct respirator cartridge or filter is crucial for protection against hazardous airborne contaminants. The National Institute for Occupational Safety and Health (NIOSH) has established a color-coding system for respirator cartridges and filters to indicate the type of protection they provide.

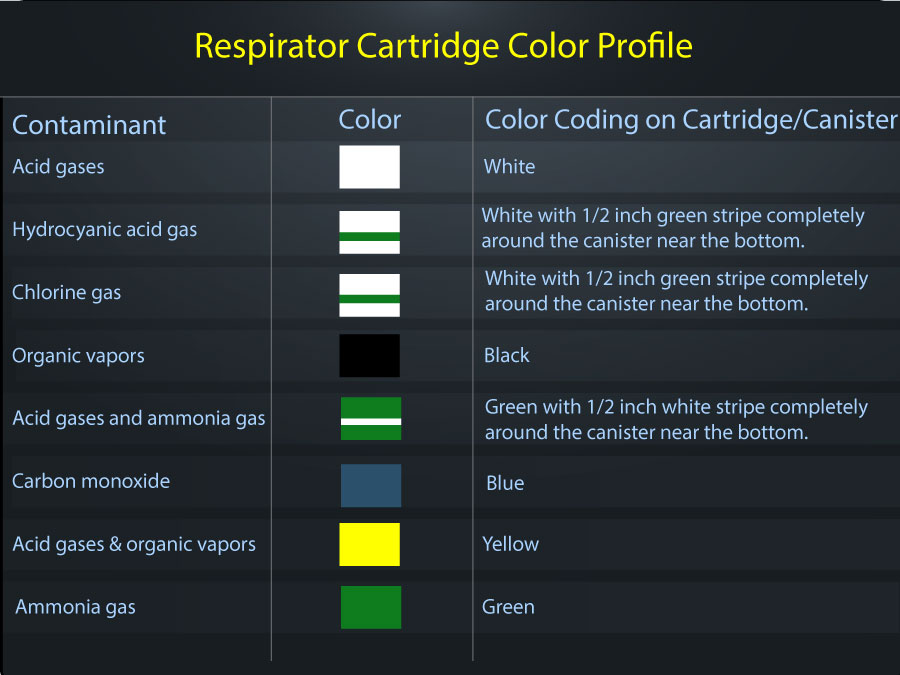

1. What are NIOSH Color Bands on Respirators?

The NIOSH color bands are used on air-purifying respirator (APR) cartridges and filters to visually identify the type of contaminants they are designed to protect against. Each color corresponds to a specific hazard class, such as organic vapors, acid gases, ammonia, or particulates.

Why the Color Bands Matter:

- Ensures workers use the right cartridge/filter for the hazard.

- Prevents accidental exposure to toxic gases or particulates.

- Makes it easier to identify correct replacement cartridges.

2. NIOSH Color Codes for Respirator Cartridges & Filters

| Color | Protection Against | Examples of Contaminants | Cartridge Type |

|---|---|---|---|

| Black | Organic Vapors | Benzene, toluene, xylene, paint fumes, pesticides | Organic Vapor (OV) |

| White | Acid Gases | Chlorine, sulfur dioxide, hydrogen chloride | Acid Gas (AG) |

| Yellow | Organic Vapors & Acid Gases | Paint thinners, pesticides, chlorine, ammonia | Organic Vapor/Acid Gas (OV/AG) |

| Green | Ammonia & Methylamine | Ammonia, fertilizers, refrigeration chemicals | Ammonia/Methylamine (AM/MA) |

| Olive | Multiple Chemical Gases & Vapors | A combination of organic vapors, acid gases, ammonia, etc. | Multi-Gas/Vapor |

| Magenta (Pink) | HEPA (High-Efficiency Particulate Air) Filter | Asbestos, lead dust, silica, biohazards, radioactive materials | P100 |

| Blue | Carbon Monoxide (CO) | Carbon monoxide (requires continuous monitoring) | CO (Carbon Monoxide) |

| Brown | Specific Industrial Gases | Hydrogen fluoride, certain chemical processing gases | HF (Hydrogen Fluoride) |

| Orange | Mercury Vapors & Chlorine Gas | Mercury vapor, chlorine | Mercury Vapor/Chlorine Gas (Hg/Cl) |

3. Particulate Filters and Their Color Codes

In addition to gas/vapor cartridges, some respirators require particulate filters to protect against dusts, mists, fumes, and biological hazards.

| Filter Type | NIOSH Rating | Protection Against |

|---|---|---|

| N95 (White or No Color Band) | 95% efficient, Not resistant to oil | Dusts, biological agents (e.g., TB, flu) |

| R95 (White or No Color Band) | 95% efficient, Somewhat resistant to oil | Dusts, mists, certain oil-based particulates |

| P95 (White or No Color Band) | 95% efficient, Strongly resistant to oil | Oil-based & non-oil particulates |

| P100 (Magenta/Pink) | 99.97% efficient, Strongly resistant to oil | Lead, asbestos, silica, biohazards, highly toxic particulates |

4. Selecting the Right Cartridge for HAZWOPER Work

How to Choose the Right Filter/Cartridge:

- Identify the Hazard

- Conduct air monitoring to determine if you are dealing with organic vapors, acid gases, particulates, or a combination.

- Match the Hazard to the Correct NIOSH Color Band

- Example: If working with benzene or paint thinners, choose a black (Organic Vapor) cartridge.

- Consider Particulate Exposure

- If dust or mist exposure is present, use a P100 filter (magenta) in combination with the gas cartridge.

- Check NIOSH Approval & Expiration Dates

- Cartridges and filters degrade over time, so follow replacement schedules based on breakthrough times.

- Fit Test & Seal Check

- Half-face and full-face respirators require an annual fit test and a seal check before each use.

5. HAZWOPER Applications & Examples

| HAZWOPER Task | Common Hazards | Recommended Respirator & Filter |

|---|---|---|

| Chemical Spill Cleanup | Organic solvents (benzene, toluene), Acid gases | OV/AG cartridge (Yellow), P100 filter if particulates present |

| Pesticide Handling | Organic vapors, aerosols | Organic Vapor cartridge (Black) + P100 filter |

| Confined Space Entry | Hydrogen sulfide (H₂S), Low oxygen | SCBA or Air-Supplied Respirator |

| Lead/Asbestos Removal | Lead dust, asbestos fibers | P100 filter (Magenta) |

| Ammonia Refrigeration Work | Ammonia gas | Ammonia cartridge (Green) |

6. Key Takeaways

- NIOSH color bands help workers quickly identify the right respirator cartridges for the hazard.

- Combination cartridges (e.g., yellow for OV/AG) provide protection against multiple hazards.

- P100 filters (Magenta) should be used for toxic dusts like lead and asbestos.

- Cartridges have limited service life—follow replacement guidelines based on contaminant concentration and exposure duration.

- Fit testing & seal checks are essential for proper protection.

Sources

Emergency Response and Preparedness

OSHA HAZWOPER Hands-on Training Requirement

Medical Surveillance Requirements

U.S. Occupational Safety and Health Administration

https://www.osha.gov/laws-regs/standardinterpretations/1992-08-27-1

U.S. Environmental Protection Agency

https://www.epa.gov/laws-regulations/summary-resource-conservation-and-recovery-act

Related Articles

Building a HAZWOPER Safety Culture

HAZWOPER Hands-on Training Discussions with U.S. OSHA