Exclusion Zone at a HAZWOPER Site: A Comprehensive Guide

An Exclusion Zone (Hot Zone) at a HAZWOPER (Hazardous Waste Operations and Emergency Response) site is the most hazardous area, where contamination is present, suspected, or likely to occur. This zone requires strict safety controls to protect workers, prevent the spread of hazardous materials, and ensure compliance with the Occupational Safety and Health Administration (OSHA) regulations.

1. Purpose of the Exclusion Zone

The Exclusion Zone is established to:

- Isolate hazardous materials and prevent contamination from spreading.

- Protect workers by ensuring only properly trained personnel with adequate Personal Protective Equipment (PPE) enter.

- Control access and track personnel movements for safety and accountability.

- Facilitate decontamination by ensuring all personnel and equipment go through a decontamination corridor before exiting.

2. Components of the Exclusion Zone

A. Hazardous Material Presence

- This zone contains chemical, biological, radiological, or toxic substances that pose serious health risks.

- It is often the location of a spill, leak, or contamination site.

B. Restricted Access

- Only authorized and trained personnel can enter.

- Workers must follow strict entry and exit protocols to limit exposure.

C. Personal Protective Equipment (PPE) Requirements

- PPE levels are determined based on OSHA’s PPE classification system:

D. Continuous Hazard Monitoring

- Air quality monitoring detects hazardous vapors, gases, or particulates.

- Temperature and oxygen levels are continuously checked to prevent asphyxiation.

- Radiation detectors are used if radioactive materials are present.

E. Emergency Response Plan

- Pre-planned evacuation routes and alarms are established in case of an emergency.

- First aid stations and emergency decontamination showers must be available near the zone.

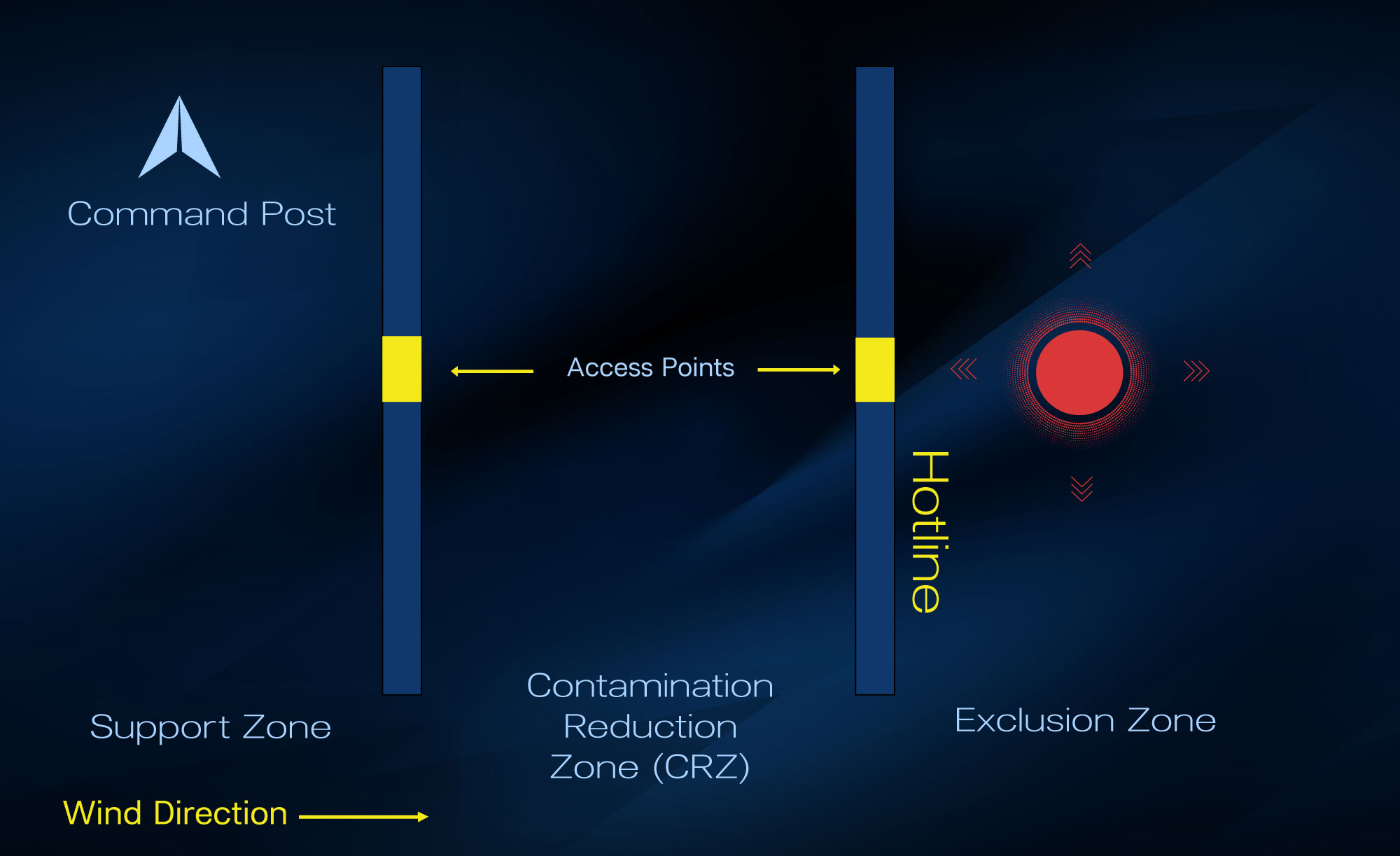

3. Site Control Zones in HAZWOPER Operations

The Exclusion Zone is part of a three-zone system designed for safe hazardous material handling:

1. Exclusion Zone (Hot Zone) – High Risk

• The most contaminated and dangerous area.

• Only personnel with proper PPE and clearance are allowed.

• All personnel and equipment must be decontaminated before exiting.

2. Contamination Reduction Zone (Warm Zone) – Moderate Risk

• Also called the Decontamination Corridor.

• Personnel leaving the Exclusion Zone must pass through multiple decontamination stations.

• PPE may be removed in stages as contamination levels decrease.

3. Support Zone (Cold Zone) – No Risk

• The safe zone where administrative tasks, equipment preparation, and breaks occur.

• Personnel do not require PPE.

• Serves as a staging area for medical assistance, monitoring, and logistics.

4. Safety Measures and Exclusion Zone Setup

A. Marking the Exclusion Zone

- Brightly colored barricades, cones, or fencing should define the boundaries.

- Warning signs must be posted:

- “DANGER: HAZARDOUS MATERIALS AREA – AUTHORIZED PERSONNEL ONLY”

- “EXCLUSION ZONE – PPE REQUIRED”

B. Entry and Exit Protocols

- Personnel must sign in and out at controlled entry points.

- Workers cannot enter without a safety briefing and PPE check.

- Exit requires full decontamination and a post-work health assessment.

C. Decontamination Stations

- Located in the Contamination Reduction Zone (Warm Zone).

- Includes:

- Rinse showers

- Chemical neutralization stations

- PPE removal stations

- Final medical assessment checkpoint before entering the Support Zone.

D. Emergency Response in the Exclusion Zone

- Emergency alarms must be installed to signal hazardous conditions.

- Fire suppression systems should be available.

- Backup rescue teams must be on standby with appropriate PPE.

5. OSHA Regulations Governing Exclusion Zones

OSHA regulates hazardous material site operations under 29 CFR 1910.120. Key requirements include:

- Hazard Assessment: Employers must evaluate all potential dangers within the Exclusion Zone.

- PPE Training & Certification: Workers must be trained in selecting, using, and decontaminating PPE.

- Air Quality Monitoring: Regular testing for oxygen levels, flammable gases, and toxic vapors is required.

- Emergency Planning: Employers must prepare detailed HAZWOPER Site Safety Plans, including evacuation and medical response protocols.

6. Real-World Example of an Exclusion Zone in Use

Scenario: Chemical Spill at an Industrial Site

- A large chemical spill occurs at a manufacturing plant.

- Emergency responders arrive and establish an Exclusion Zone around the spill.

- Workers wearing Level A PPE enter the zone to identify the chemical and control the leak.

- All personnel leaving the Exclusion Zone must go through decontamination procedures before moving to the Support Zone.

- Air monitoring continues until contamination levels drop to safe limits.

- The Exclusion Zone is reduced or eliminated once the site is confirmed safe.

Conclusion

The Exclusion Zone at a HAZWOPER site is the first line of defense in hazardous material operations. It ensures that:

- Workers remain protected from toxic exposure.

- Contamination is contained within the designated area.

- Emergency response is controlled and efficient.

By following OSHA regulations and proper site management protocols, the Exclusion Zone helps minimize risks and prevent hazardous material incidents from escalating into full-scale disasters.